Issue

Isopropyl alcohol is used for washing uncured resin from 3D prints make by a SLA printer. Eventually, the alcohol becomes saturated with resin and needs to be replaced. The problem is both cost and disposing of the saturated alcohol.

Solution

An alternative is to recycle the saturated alcohol thru the following steps to remove the resin.

First put the saturated alcohol into a clear container. The clarity and color of the saturated alcohol depends on the color of the prints that were washed and how saturated the alcohol is. The photos here are after washing a white resin. I didn’t let the alcohol become fully saturated since I’ll be printing in a different color and didn’t want any possibility of a white film on the upcoming prints.

Next place the container in the sun until it turns cloudy or put it in the curing station for 10 minutes. This cures a portion of the resin which allows it to be filtered out thus reducing the volume of scum in the distiller.

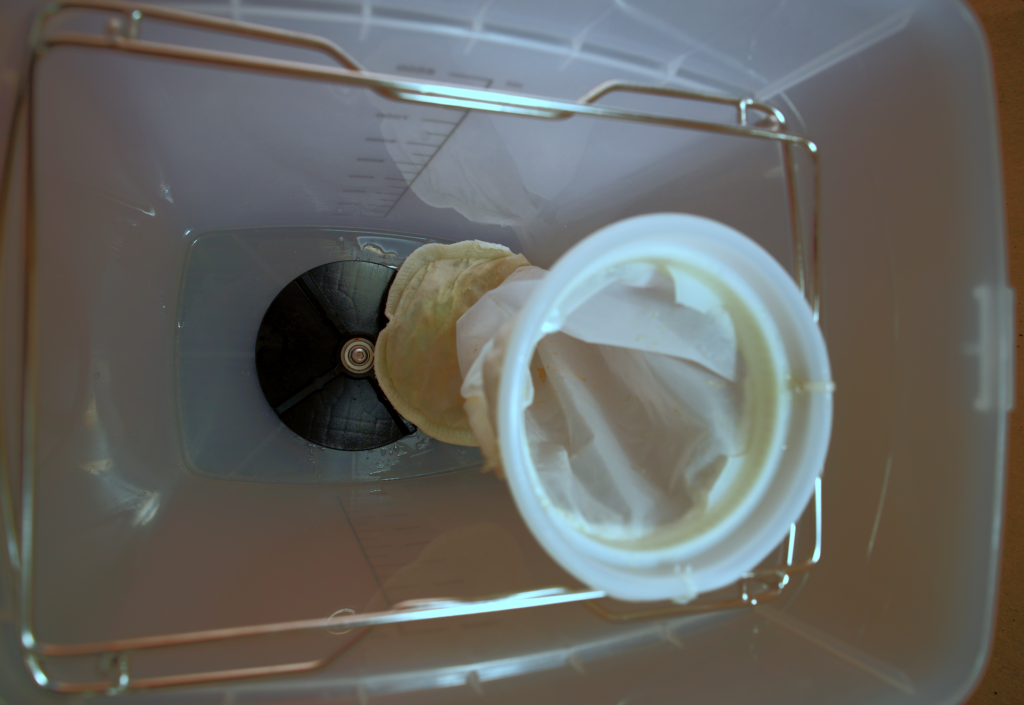

The cured resin can now be filtered out using a fine mesh filter bag such as this 50um aquarium filter.

The final step is to distill the partially clean resin to remove the remainder of the resin still in solution. I use this alcohol distiller since it allows the the temperature to be set. Isopropyl alcohol boils at 82.6ºC so setting the distiller to 83ºC boils the alcohol with less danger than using a water distiller. If you are running the distiller indoors, do so in a room with an exhaust fan to avoid both breathing the vapors and accumulating the flammable vapors.

Frequently check the distiller to avoid burning the residue. As long as the residue is still a slime it is easy to wipe the distiller clean with a paper towel. Baked on residue requires a plastic scraper to remove.

Conclusion

Recycling alcohol reduces both cost and the amount of waste involved with resin printing. The process is easy, minimizes environmental impact and the cost of the distiller and aquarium filters are cheaper than the replacement cost of the alcohol.